Cladding

Bimetallic tube

Characterization of Bimetallic Tube Made from Explosion Clad Sheets

Objective

To present the main results of the performance of the X-65/Inconel 625 bimetallic tube when evaluated in the light of the criteria established in the DNV OS F-101 standard.

DNV OS F-101 requirements

1- Tensile test

2- Impact toughness test

3- Hardness test (X-65 and on Inconel 625)

4- Shear test

5- Corrosion test (on Inconel 625)

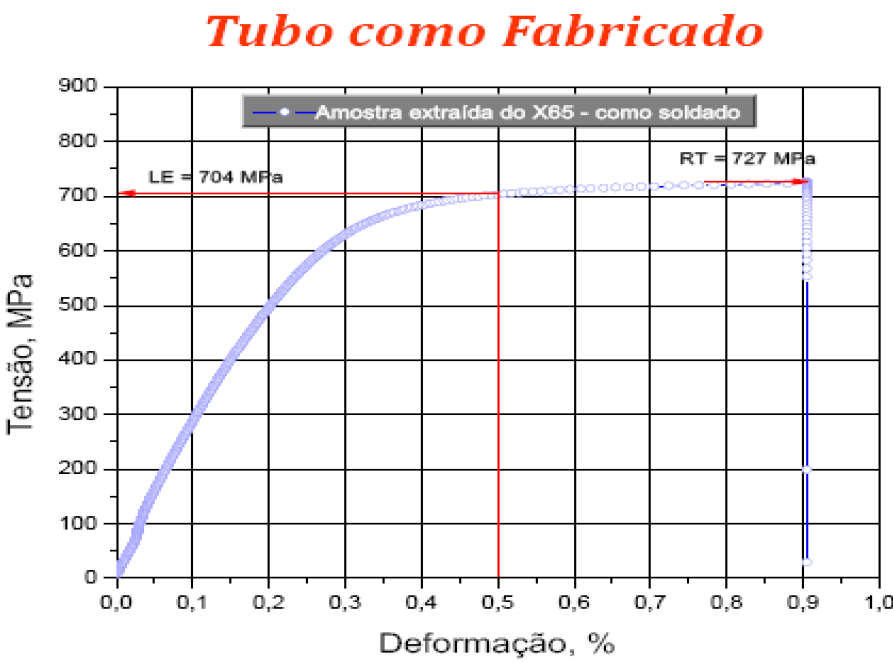

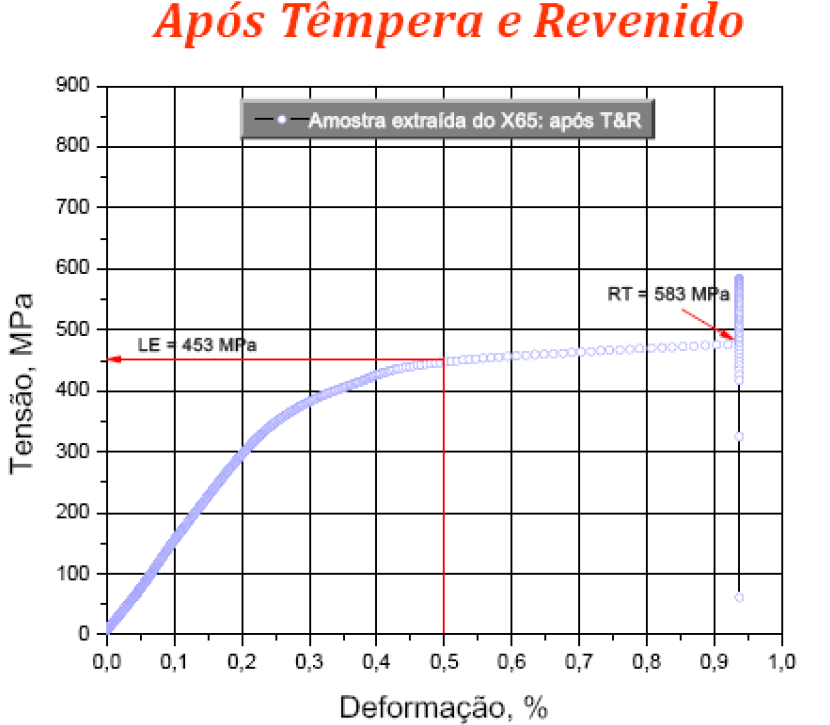

- Mechanical Properties: Tensile Testing

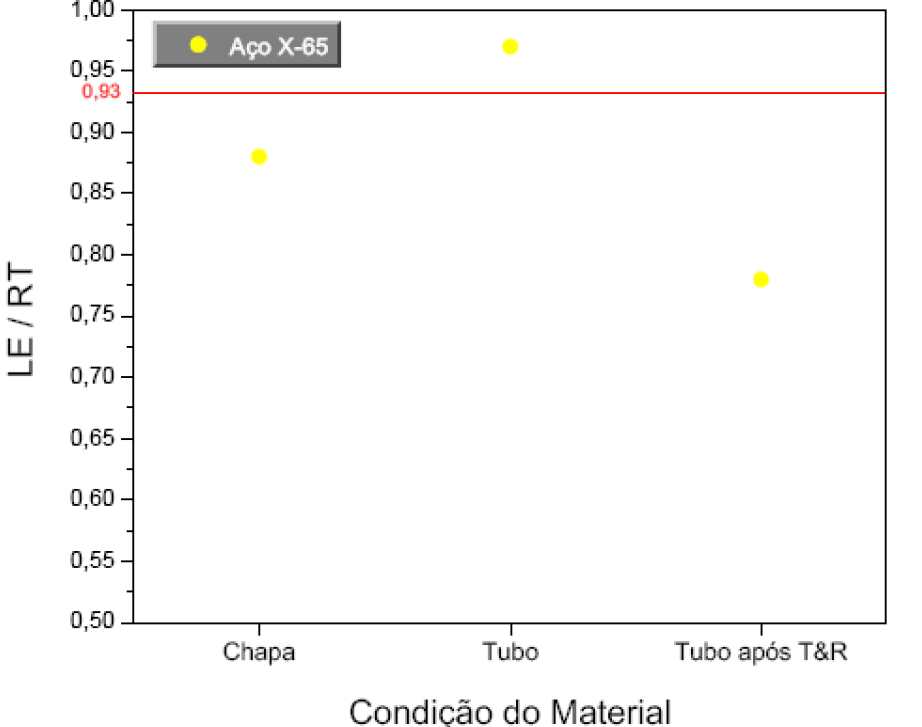

450 MPa < LE < 570 MPa; 535 MPa < LR < 760 MPa; LE/LR < 0,93

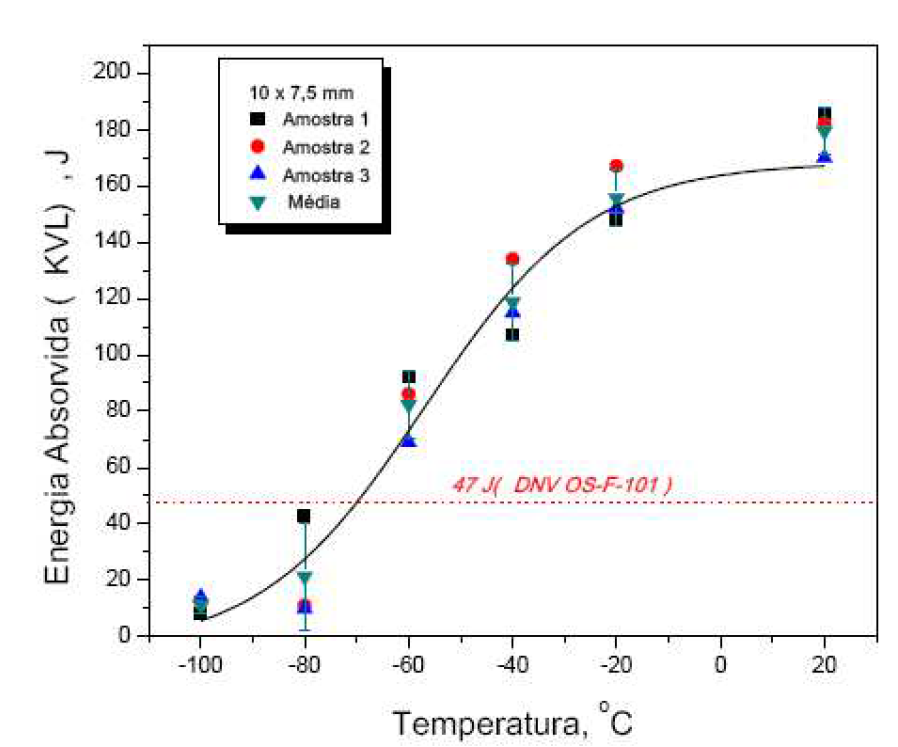

- Mechanical Properties: CVN Impact Test

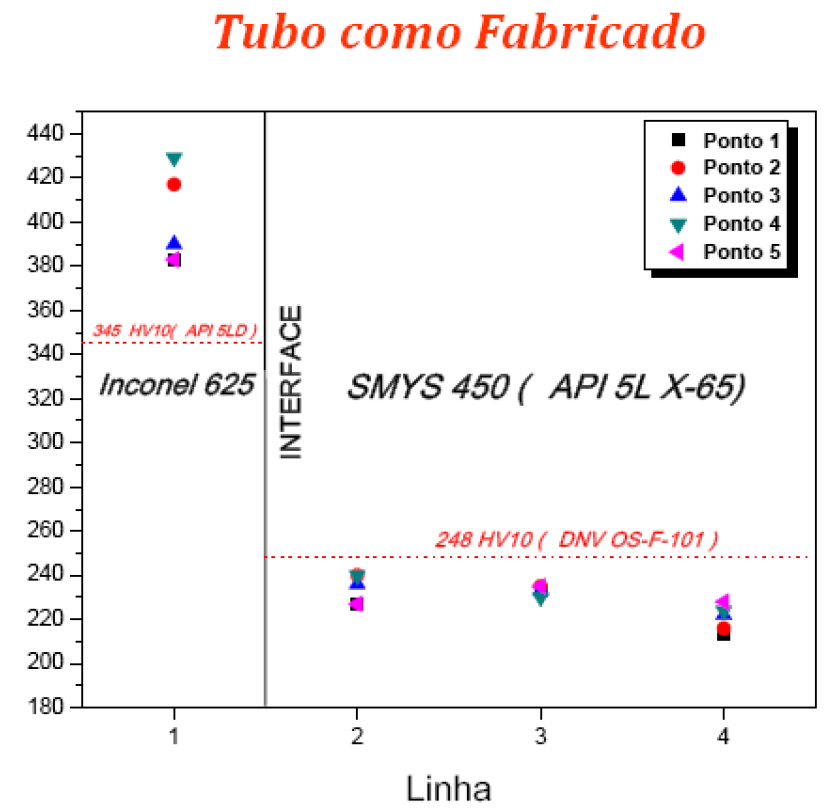

- Mechanical properties: Hardness test

X-65 steel < 248 HV10 Inconel 625 CRA < 345 HV10

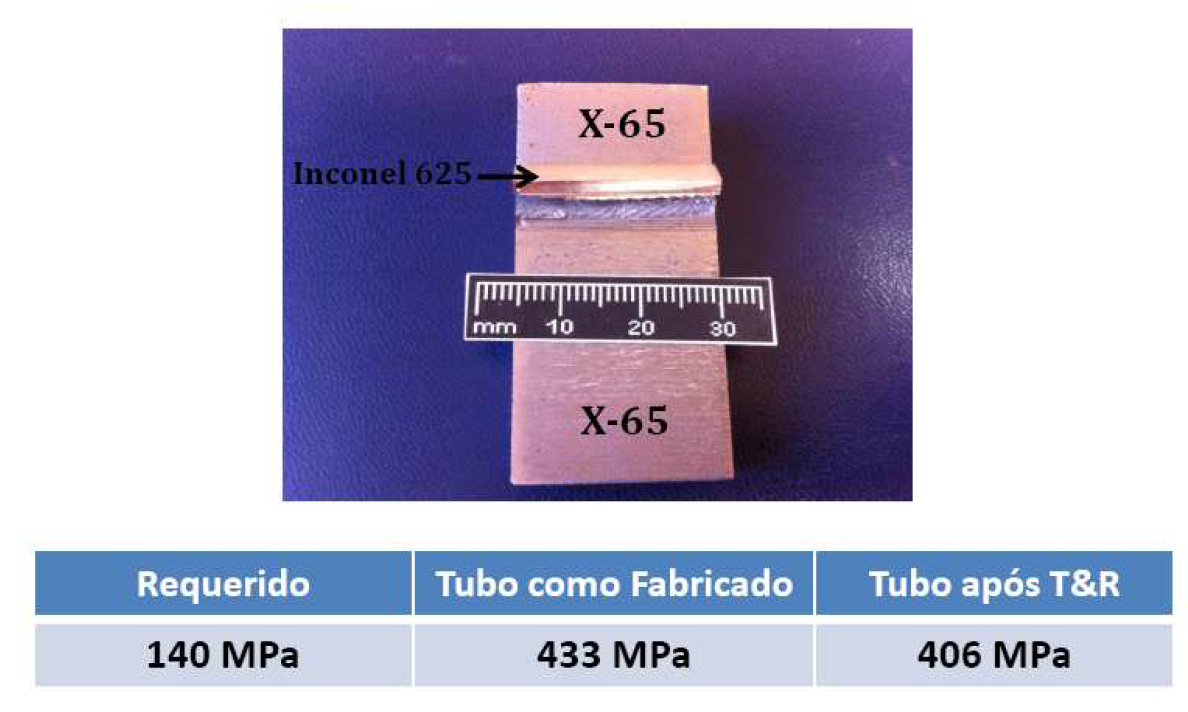

- Mechanical Properties: Shear Test

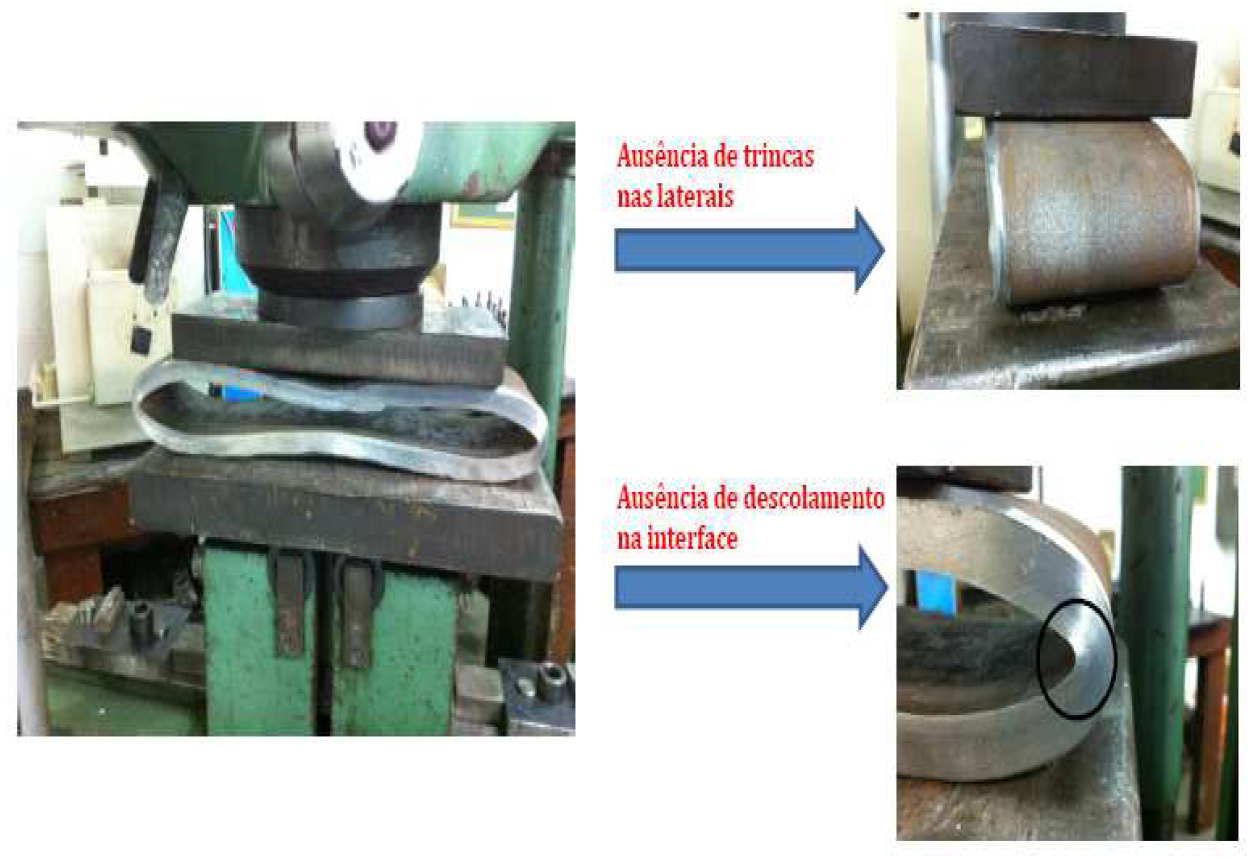

- Mechanical properties: Flattening test

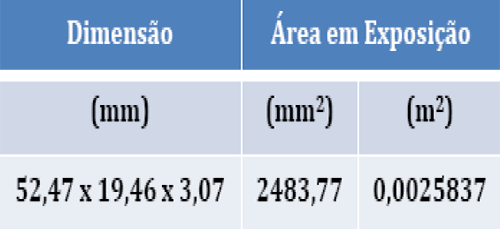

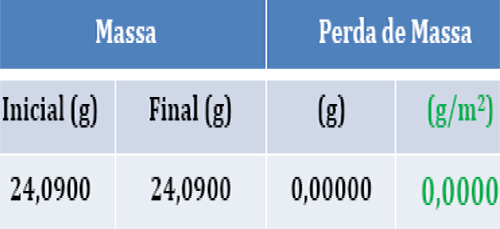

- Corrosion resistance: ASTM G48 Method A test

Immersion in ferric chloride at 50°C for 24 hours

- Heat treatment

Heat treatment (stress relieving) depending on the alloys involved must be carried out in accordance with the tolerances of the ASTM A-20 standard and under the guidance of our technical department.

- Performance

Disk performance in the press.

Unrolling sheet metal in the calender.

- Tests

Destructive tests applied to clad plates according to ASTM A-263, A-265, A-20, B-432, DIN-71 and corrosion susceptibility conf. A-262 Practice 'E' or other requested standards are carried out with first-rate and absolutely reliable partners and laboratories. We are perfectly prepared to provide the 'Hydrogen Disbonding Test for Bimetallic' according to ASTM G 146 on special request.

Removal of specimen with water jet.

Conclusions

1- When analyzing the results obtained for shear in the tests carried out on ASTM A240 Tp 316L x ASTM A516 Grade 70 carbon steel clad plates, it can be seen that the explosive welded plate provides shear strength on average 4 times the minimum required by the ASTM A264 standard.

2- The final product manufactured from explosive welded plate in Inconel 625; 4.0 mm x Steel X-65; 12.7 mm met all the requirements set out in DNV OS F-101. However, this manufacturing route is not validated for use in subsea pipeline systems if DNV OS F-101 is adopted as the acceptance criterion for this type of construction.

3- The final product made from Inconel 625; 4.0 mm x Steel X-65; 12.7 mm blast-welded plate can be used in any other application where DNV OS F-101 is not required by contract.

4- Explosive welded sheets are manufactured from a wide variety of metal combinations. The criteria used to determine the welding parameters are the mechanical and metallurgical characteristics of the materials to be joined, thus guaranteeing the quality required by end customers.

5- Explosive welded sheets have been manufactured in Brazil for more than 30 years and MULTICLAD has made a substantial contribution to the domestic industry in terms of its capacity and competitiveness in relation to similar imported products.

6- By importing clad sheets, whether obtained by bonding or in a vacuum, we are indirectly importing carbon steels that are widely produced by Brazilian steel mills. Note that the materials that make up these imported clad sheets are manufactured in Brazil.

7- The content of this report demonstrates MULTICLAD's technical capabilities as a supplier of services for the manufacture of explosive welded plates, providing technical support to clients from the quotation stage to the final manufacture of the equipment.